ONTRAK CONTROL SYSTEMS AT A GLANCE

Tom Fortin-Engineering Manager

The vast majority of products manufactured by Ontrak Control Systems are custom products developed for OEMís in various industries including medical instrumentation, security, industrial control and Point-Of-Sale.

Valerie Wilson- Controller

Valerie is our controller, and the main contact for ordering. She can be reached at (705) 671-2652 or by EMAIL.

All Products Always in Stock

We prefer the Just-in-Case inventory system to ensure you never have to wait for the products you need.

Quality and Test

SMT Inspection Station

Visual inspection of both through-hole, and SMT fine pitch components is completed on every product.

ADU70 Series Test Station

All products, whether stock or custom, are subject to complete functional verification before delivery ensuring reliable operation in the field.

ADU200 Series Test Station

EMC and Safety Testing

Hi-Pot and Ground Bond Testing

All CSA/UL and TUV certified products are subject to Hi-Pot and ground bond testing.

CE/FCC Emissions/Immunity Testing

Located in our sister company, Fortin Discovery Lab, a Laplace Instruments GTEM facilitates RF emissions and immunity tests on all products.

ESD 61000-4-2 Test Table

An ESD test station, and auxillary equipment for EFT etc. permit quick CE certification entirely in house.

Through Hole and SMT Production Capabilities

DDM Novastar Wave Solder Machine

Production of PCB assemblies is handled by automated assembly and soldering machines from DDM Novastar.

DDM Novastar PNP Machines

Both standard, and dual-vision pick-and-place machines ensure precise component placement.

DDM Novastar Oven and Stencil Printer

A three zone oven, and stencil printer round out the line.

Enclosure CNC Machining

Enclosure Production Machining

Isel CNC units are used to machine ADU enclosures to suit the range of products.

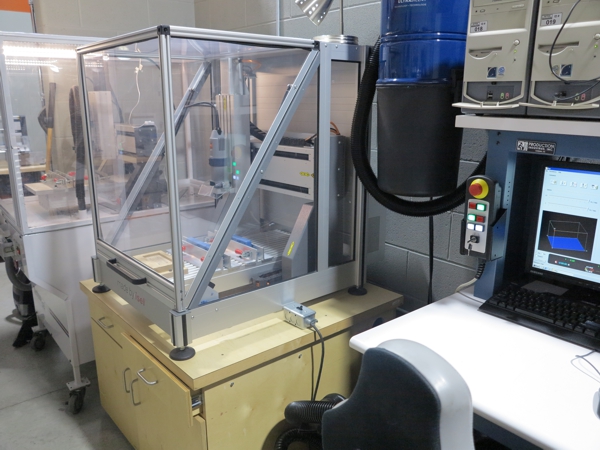

ISEL Prototype Machining Centers

Custom cut-outs for our standard ADU enclosures can be turned around in 24 hours.